FROM FACTORY TO LUXURIOUS LIVING

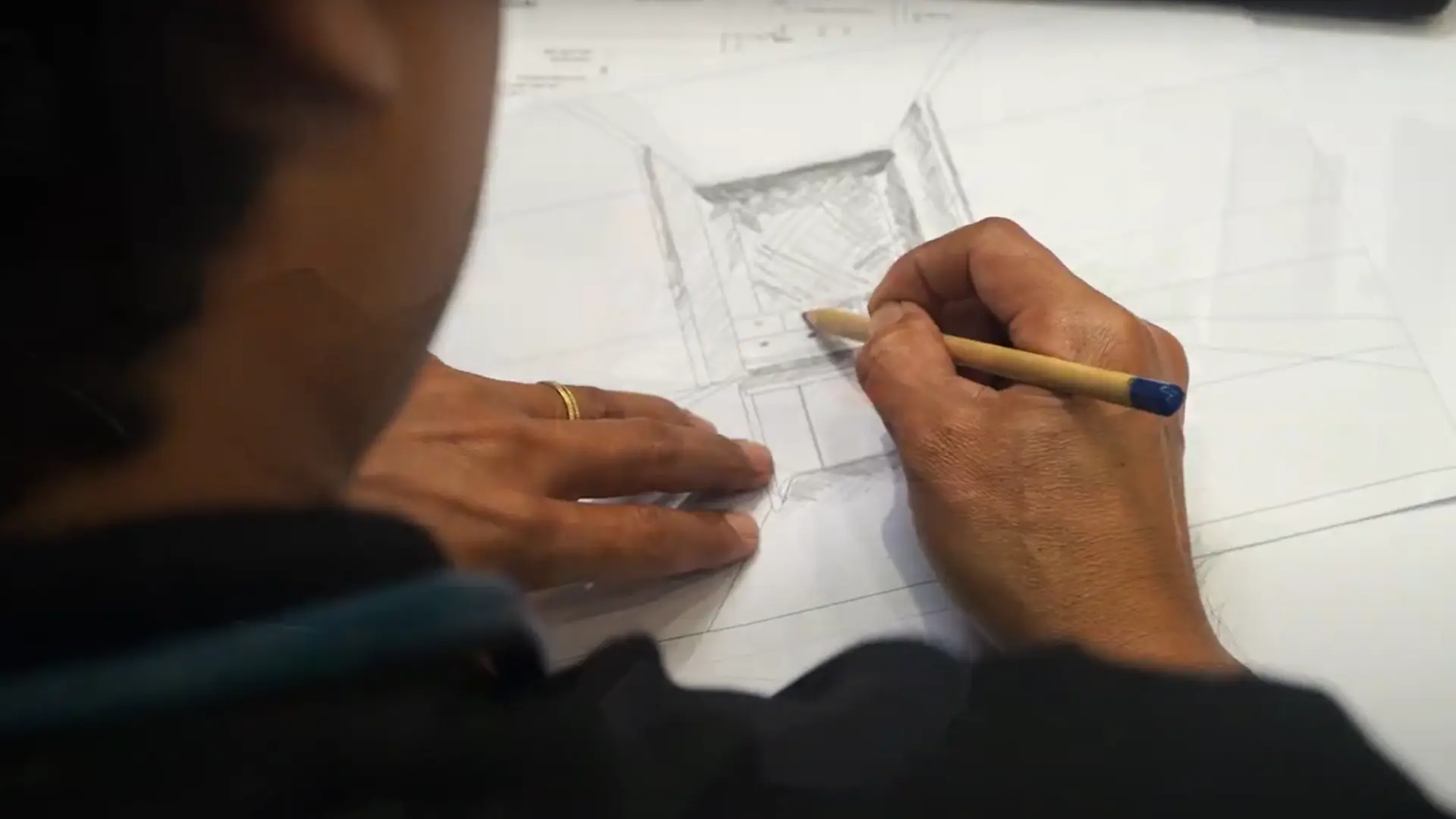

Our shopdrawing team receives design concepts from clients and consultants, then develops them into detailed technical drawings. Each drawing is meticulously constructed to reflect accurate dimensions, structures, and materials, while ensuring feasibility for production and installation. This foundational step defines the production roadmap and enables precise quality control from the outset .

Based on the technical drawings, our production engineering team designs tailored fabrication processes for each product. Every step is carefully planned to ensure precision, consistency, and compatibility with various materials. At DNM, our engineering systems are built for flexibility — enabling us to adapt and fulfill specific requirements for structure, quality, and aesthetics, even for the most demanding hospitality and high-end residential projects.

CUSTOM - DEVELOP IN LINE WITH DESIGN INTENT

UPHOLSTERY

We offer a diverse range of high-quality upholstered furniture — including sofas, armchairs, dining chairs, and bar stools — crafted with precision tailoring and meticulous finishing. Each piece is designed not only for functionality and durability but also to embody refined aesthetics that elevate any hospitality space.

Every detail is meticulously refined — from the solid frame structure and carefully tailored upholstery to the exquisite finishing — harmonizing artisanal craftsmanship with technical precision. Each piece reflects our deep commitment to aesthetic beauty and lasting functionality in every product we create.

Sustainably sourced hardwoods are carefully selected for their durability, structural integrity, and natural grain beauty. Each timber is dried, treated, and calibrated to meet the highest hospitality-grade standards.

Our woodworking process integrates advanced machinery with refined joinery techniques to ensure strength, precision, and longevity. Surfaces are meticulously planed, sanded, and prepared for finishing — laying the foundation for both visual harmony and lasting performance in every piece.

WOOD & WOODWORK

Our metal workshop is equipped with modern machinery for cutting, bending, welding, and surface finishing. From load-bearing structures to refined decorative elements, every product is crafted with high precision and durability. Various metals such as stainless steel, aluminum, and powder-coated iron are carefully processed to meet premium hospitality standards, ensuring seamless integration with wood, upholstery, and glass components.

The metal finishing process is fully integrated in-house, starting with precise CNC machining, followed by bending and pressing to achieve the desired form. Surface treatments include brushing, polishing, and PVD coating to create a premium aesthetic while enhancing durability and oxidation resistance. Every detail is closely monitored to ensure crisp edges, smooth finishes, and consistent quality across all final products.

METAL

Our facility handles a full range of processes including CNC cutting, edge grinding, pattern printing, color coating, and tempering. All glass products meet strict specifications in terms of size, safety, and versatility, making them suitable for partitions, doors, signage, tabletops, and decorative features

We supply both natural and engineered stone products that are cut, polished, and finished according to each project’s technical requirements. Stone is widely used for tabletops, wall cladding, bar counters, and other interior applications that require high durability and visual consistency.

GLASS & STONE

Our factory operates a closed-coating line covering all key stages: base drying, priming, coloring, and final finishing in gloss or matte. Each coating zone is functionally separated to minimize dust and maintain controlled environmental conditions.

Advanced machinery and skilled technicians enable efficient finishing on various surfaces such as veneer, MDF, and solid wood. Every coating layer is thoroughly checked for thickness, adhesion, and consistency, ensuring uniform quality across large-scale production.

PAINT

In the assembly section, every component is precisely connected according to technical specifications, ensuring structural integrity and high aesthetic standards for the finished product. Skilled craftsmen inspect each joint and connection carefully to guarantee accuracy and consistent quality before packaging.

This stage is not only the final step of the production process but also reflects the precision of the entire value chain—where every detail is refined to deliver a truly complete product.

ASSEMBLY

At Đông Ngô Manufacturer, every product undergoes rigorous in-house testing to ensure structural strength, surface durability, and long-term performance.

We comply with international standards, delivering furniture that's not only beautiful — but built to last.

Our R&D team explores new materials and refines production techniques to enhance both design and functionality.

Innovation lies at the heart of our process — creating furniture that meets modern demands with sustainability, precision, and style.

TESTING & RD

Each product is thoroughly inspected for structure, dimensions, surface finishing, and technical standards. Every stage follows a specific quality control process to ensure precision and consistency before packaging.

We use advanced packaging solutions such as shock-resistant materials, air cushions, and durable cartons to protect the products from external impacts. Each package is clearly labeled with detailed product information and shipping codes to ensure smooth and accurate delivery.

INSPECTION AND

PACKAGING

At DNManufacturer, we ensure that every product is delivered with precision and care. Our logistics process is optimized for both domestic and international shipments, with a strong focus on timing, safety, and transparency. We collaborate with trusted logistics partners to manage transportation, customs clearance, and final delivery. Products are securely packed at our facility and tracked throughout the journey, ensuring they reach the destination in perfect condition and on schedule.

LOGISTICS

MEMBERS OF ĐÔNG NGÔ GROUP